Seal Test / Sealing Test distribute|food seal strength testing : maker Six new reasons drive home the importance of determining seal integrity using these common food packaging test methods. WEBCoopertalse Horários. Coopertalse Horários e Rotas. Coopertalse Horários de Ônibus Aracaju. Antes de tudo, primeiramente os horários são de saida com origem em ARACAJU. O destino final é POCO REDONDO. Horário Rodov Velha / Horário Rodov Nova. 04:55 / 05:15 – 64 ARACAJU / CANINDE VIA ITABAIANA > R$ 27,70

{plog:ftitle_list}

WEBA Havan respondeu ao PROCON que honraria com o que foi erroneamente publicado e venderia 200 unidades desse Geladeira pelo preço abaixo do mercado. Neste momento, ainda existem unidades disponíveis para compra pelo valor de R$ 138,90, porém, o estoque pode acabar a qualquer momento, pois a Havan se comprometeu a vender .

Six new reasons drive home the importance of determining seal integrity using these common food packaging test methods.

Testing the integrity of package seals helps ensure that food packaging provides required product protection. Sustainable packaging alternatives, lower cost packaging, and variations in production line sealing parameters are frequently .Claire Sand | Nov 10, 2021. Enhanced package seal integrity is once again top-of-mind due to recent supply and demand challenges that include these six reasons: Obtaining consistent .As a result, squeeze-out increases linearly with increasing pressure because the extra force will push out the molten sealant easily from the sealing area. 46. 5.1.4 Seal bar design. The profile of sealing bars affects the seal quality based on bar width, segregation pattern, and type of material.• Distribution Cycle: the sequential listing of the test schedules employed to simulate the hazard elements expected to occur for a specific routing from production to composition (most fall into DC13 encompassing both air and truck. • Assurance level: the level of intensity based on the probability of occurring in a typical distribution cycle

The easiest to do is hot water seal. Use distilled or demineralised water with a conductivity below 150 microsiemens and a pH of about 6 (5.5-6.5 is not uncommon). . The sealing test is also described by BS EN 12373-6. I don't know if it is exactly the same as the ASTM, I haven't carried out any gap analysis to find out. After the sealing test, discharge pressure and remove the long tapered slot from the test cell, pour away the fluid. After open the fracture slot, we can investigate the position, thickness and microstructure of plugging zone. . More force chains inside the multi-layer seal barrier can distribute the force together, the thicker plugging zone .

Seal test of tubing thread in high pressure gas well is a new technology currently, but there is no uniform standard regarding the accurate sealing test pressure, frequently improper sealing test pressure can easily lead to damage and fatigue failure of tubing.If your house qualifies, you might be able to get a complete home air sealing package (including duct sealing and insulation upgrades) for ZERO money upfront. Get whole-house air and duct sealing—for NO upfront cost. Yes, really. Here’s our 10-second spiel for how it works.

Residual Seal Force (RSF) • RSF is the Stress A Compressed Elastomeric Closure Flange Continues to Exert on A Vial Land Sealing Surface after Application of an Aluminum Seal (Crimping). • USP <1207.3> Seal Quality Test • Quantifying the RSF is a Test Method for the Indirect Estimation of Elastomeric Closure Compression.

package inflation seal strength test. In the Creep Test, a whole package is inflated to a constant pressure, which is then held for a specified time, resulting in a pass/fail result (see Figure 5). Early users of the method for peelable seals used the test as an analogy for the pressure difference on the seals seen in the ETOJia et al. Journal of Engineering and Applied Science Page 5 of 12 guarantee a high-pressure water seal state; Step 3: permit the ber tail to move in both X and Y directions to replicate the rotary and impact movement of the rock drill’s washing mechanism. Simulation model verication We used experimental data from pertinent literature and set the same parameters in the Keep in mind that these numbers vary quite a lot, as home size is not directly correlated to duct length or layout. DIY vs. Hiring a Pro. Labor makes up the majority of the cost to seal HVAC ducts, with around 90% of the average ,000 duct sealing total going toward labor and just 10% going toward materials for manual sealing. That means you could save upwards .

Dynamic sealing test device for shield tail grease under high water pressure was developed. . In the dynamic seal test (C2-B in Table 5), due to the relative movement, seal failure occurred. The test results are shown in Fig. 12. Table 5. . The pressure distribution in the initial stage was uniform. As the upper grease surface continued to .Der Peel-Test ist neben dem Seal-Check, dem Tintentest und der Siegelnahtfestigkeitsprüfung ein gängiges Verfahren zur Beurteilung der Siegelnaht-Qualität eines Siegelgerätes. Die Durchführung des Peel-Tests ermöglicht es, fehlerhafte Siegelungen rechtzeitig zu erkennen und zu beheben. Denn nur eine korrekt verschlossene Verpackung .Seal tests ISO11607-2 (Validation requirements for forming, sealing and assembly processes), requires Operational Qualification (OQ) of packaging devices to be carried out and documented. The OQ is requiring providing proof of: Intact seal for a specific seal width No channels or open seals No punctures or tears in seals No material delaminating or separation The OQ needs tosealing cycle but prior to the temperature of the seal reaching ambient. Refer to Test Methods F1921. 3.1.6 seal initiation temperature, n—on a heat seal curve, the sealing temperature/dwell pressure at which heat seal strength first begins to trend upward from zero heat seal strength. 3.1.7 sealing interface, n—the interface of the two web

The sealing mechanism of these seals is based on the formation of a thin lubricating and sealing oil film between seal lip and rotating shaft. In the last 30 years intensive research has been performed into the sealing mechanism of these seals. In spite of this effort the sealing mechanism is still poorly understood.7.4.1 Perform an initial inboard leak test on the sealing system in accordance with Section 7.2.1. 7.4.2 Install the plumbing and test sample apparatus with test sample(s) installed into a temperature controlled chamber. Attach a thermocouple to the exterior of the apparatus adjacent to the test sample.Package Distribution Testing; ASTM Seal Integrity Testing; Package Development. . a program in which optimal sealing parameters are determined through correlation with low leakage rates. In such programs, there are .Various criteria such as the force required and the chamfering of the sealed seam are evaluated. Alongside the seal check, the ink test and the seal seam strength test, the peel test is a common method for assessing the seal seam quality of a sealing device. Performing the peel test makes it possible to detect and rectify faulty seals in good time.

6. Seal test fixture capabilities Bench testing of rotary shaft seals Figure 2 shows the standard horizontal shaft test fixtures that are used to perform much of our instrumented rotary seal testing. These bench test fixtures are capable of testing seals up to 5” (127 mm) in diameter against various environments.The ASTM (American Society for Test & Measurement) provides a wide variety of approved and validated test methods that address sealing issues for package systems and the CS Analytical has the knowledge to assist you in defining the most optimal procedure that will help you meet the challenge you are facing.

The seal integrity of pouches is checked to verify that the packaging offers the necessary protection for the product.Seal integrity tests are widely used to evaluate sustainable packaging options for users.With the growing interest in sustainable packaging, novel structures such as monolayer recyclable flexible packaging are being tested, making it critical to ensure that the . Increasing demands for environmental accountability and energy efficiency in industrial practice necessitates significant modification(s) of existing technologies and development of new ones to meet the stringent sustainability demands of the future. Generally, development of required new technologies and appropriate modifications of existing ones . Experimental investigation has been done to evaluate the leakage performance of labyrinth seal for oil sealing on high-speed sealing test rig at different working and geometric parameters. To meet the sealing requirements of flat cable with two cores, two cable sealing test specimens were designed and tested, and a scheme of cable sealing structure that can seal the non-circular cross-section cables has been proposed, providing support for developing the cable sealing component applicable to the conductive slip ring of EDS.

Shop 3,700+ industrial commercial transportation parts available from LADD Distribution. Compare Products. Evaluate up to 10 products . Fast determination of sealing integrity; Multiple test fixtures; Easy load and release of test samples; Timer adjustable from 8 – 120 seconds (only with integrated AD-3050 Seal Test Equipment timer version .

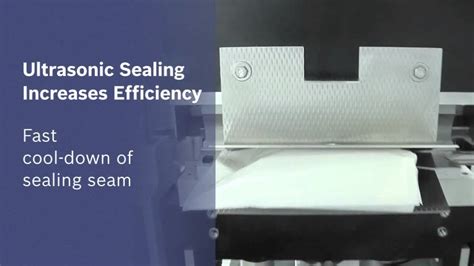

ultrasonic seal testing

The test procedure may be used to test seals of alternate size and design or using alternative media but such deviations shall be detailed separately on the report form and the results shall not be used to determine the minimum operating temperature of seals .To test the integrity of mechanical seals fitted with a secondary containment seal. This document is general in nature and does not refer to site specific requirements. The site has the responsibility for ensuring that tests are carried out.

karl fischer titration coulometric volumetric distributor

Rating List. For older ratings, check the History page. There is also a History of top ladies.

Seal Test / Sealing Test distribute|food seal strength testing